An experiment to see how quickly a wooden cutting board is rendered unusable

I made this cutting board and designed it to fail, but it didn’t fail as I expected! Here are the “bad decisions” that I made in an attempt to accelerate the failure of the cutting board.

Low density wood

I used butternut, which is a hardwood on the softer end of the spectrum. Butternut has a specific gravity of 0.43 which is about 40% lighter than hardwoods typically used for cutting boards such as beech (0.72) and hard maple (0.71). Harder woods will surely stand up to knives better than softer woods, right?

Carved letters to trap food and make it hard to clean

Wooden objects don’t do well in the dishwasher, so can’t be sanitized with heat like other dishes. I routed letters into the working surface on each side at the top with a router. Would small bits of food get lodged in the letters, making cleaning difficult or impractical?

Include a split and broken section, and sapwood

As a bolder experiment, and part of my relentless push to fail, I elected to not cut off the end where some of the wood fibres has split off, and a crack was showing in the end grain. It was an obvious place for bacteria to collect and mould to grow, but I wanted to know how quickly that would happen. Sapwood is the typically lighter band of wood that is located at the outside of the tree is generally considered less durable and is usually less dense as well. In traditional woodworking, sapwood is considered a defect. In this cutting board, sapwood comprises the top quarter.

Used a piece of wood prone to warpage

For stability, quartersawn wood where the growth rings run near vertical when you look at the end grain is unquestionably the best. Quartersawn wood is less likely to cup, twist, or warp. Rift sawn wood is the next best with growth rings around 45 degrees, and flat sawn lumber with growth rings running more or less horizontally is generally the least stable and most likely to warp. I used a single piece of wood quartersawn at the top, rift sawn at the middle, and flat sawn at the bottom.

No special care instructions or treatment for this cutting board

I threw the cutting boards into the cutting board drawer of our kitchen right alongside the plastic and wood composite ones with no instructions to my wife or kids on how to use or not use them. (They have, however, been educated that wood never goes in the dishwasher.)

Time to conclude the experiment

Today, after two years of regular use, I decided to retire the cutting board. It was used for bread, produce, raw and cooked meat on a daily basis with straight and serrated knives. The actual cutting surfaces are in pretty good condition. There are obvious knife marks, but they look like scratches as if somebody took a pointed wooden stick and dragged it across the board. (All pictures here were taken today.) The cutting board is also remarkably flat. It doesn’t rock at all on my countertops.

The lettering looks quite good – food didn’t collect in there, escaping cleaning as I thought it might. We washed the cutting board with hot soapy water and a cloth, giving it no more of a scrub than a plate. I don’t recall ever using a dish brush to scrub food out of the letters. Looking closely, the letters look a bit fuzzy on the end grain walls which might be due to repeated wet/dry cycles during washes. Perhaps someday I will try a bolder experiment with lettering right through the middle section of the cutting board that gets the most use.

But the real surprise is that the broken grain and crack in the end grain appears fine – there is no darkening or discolouration visible! Ultimately, I chose to retire the cutting board because other areas of the end grain were showing discolouration. I could have, and perhaps should have, replaced them as soon as I noticed the discolouration, but it wasn’t until today that I got around to finishing the replacements.

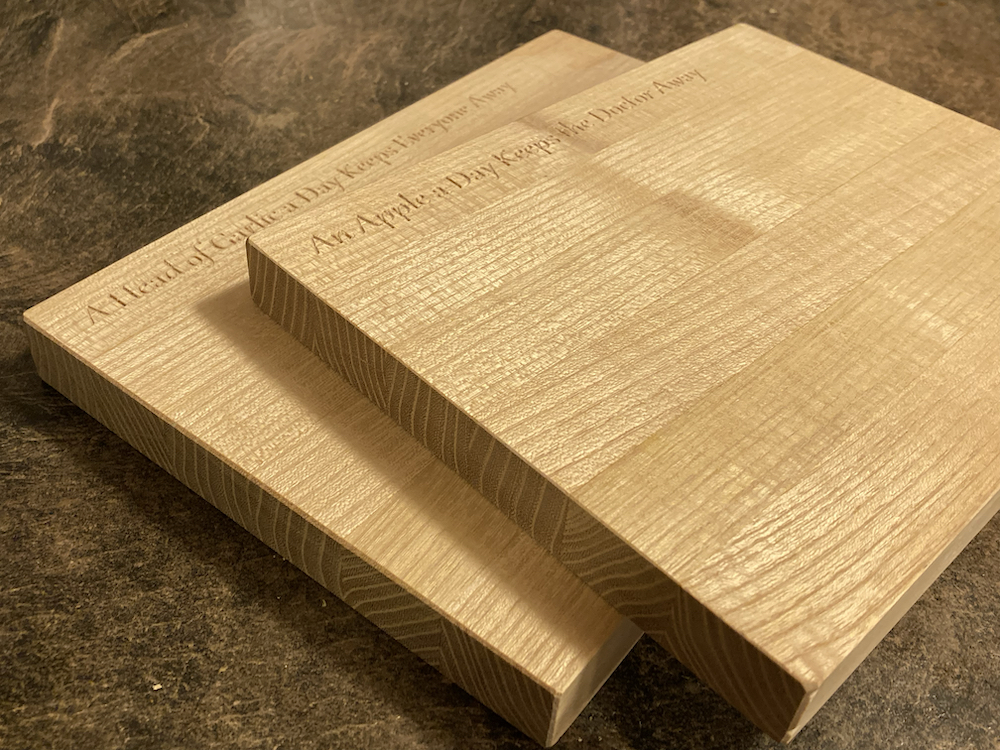

The new cutting boards are made of black locust (0.77 specific gravity), and laminated from 6 pieces. Let’s see how these hold up! If my attempt at failure lasted for 2 years, I’m guessing these will last a lot longer!