“The list of Votator applications has grown very long in the more than 80 years since it was introduced, and I would say there is no one whose life has not been touched by a product heated or cooled in a Votator.” – Tony Mathis, application engineer and product manager for Vogt Freezers and the Votator.

votator (plural votators)

1. a machine that cools and kneads liquid margarine etc., preparatory to packaging

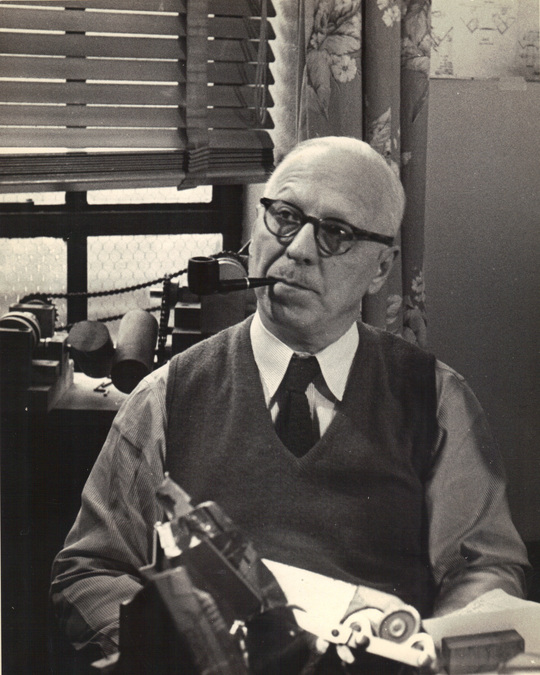

I grew up knowing that my dad (1891-1973) was the inventor of an important manufacturing process that had to do with liquids and food and that it was called the Votator, a corny sounding moniker that fit his delight in corny humor.

There were photographs on the walls of his office from trade advertisements related to products:

and references in newspaper interviews citing him as the inventor. To my recollection there were no pictures of the actual machine that had been created in an era long before my time and I certainly was never made to understand what it did specifically and how it worked. Had anybody asked me “What’s a Votator?” I couldn’t have answered.

In his second contribution as guest commentator (click here to read about the Vogt Instant Freezer and the MelORol) Tony Mathis answers that very question (“I have heard those exact words a thousand times.”)

By the way, the Votator is not a relic of the 20th century: it is manufactured at this very moment and in use world wide: “on all continents except Antartica!”

A very technical description of the crystallization process appears at the end of the post.

THE EARLY USES OF THE VOTATOR SCRAPED SURFACE HEAT EXCHANGER

By a Former Product Manager for the Votator Heat Exchanger

In the late 1920s, inventor Clarence W. Vogt of Louisville, Kentucky patented a process and machine for continuously freezing ice cream and sherbet, and also for processing lard, shortening, margarine, confections, salves and other materials “…wherein it is desirable to alter the temperature, plasticity or structure while being agitated or whipped.” This breakthrough technology would go on to revolutionize the food and dairy industry, introducing continuous production methods for viscous or crystallizing products where inefficient, inconsistent batch production had been the norm. The Vogt Instant Freezer was marketed for continuous ice cream production by Cherry-Burrell Corporation beginning in 1928, while other novel applications were pursued by Vogt Processes. This company became the Votator Division of Girdler Corporation in 1931, and Clarence Vogt was its first Vice President.

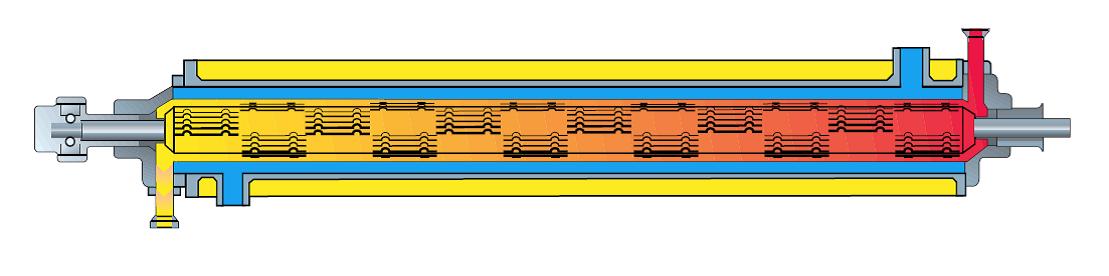

The Vogt Instant Freezer and the Votator are both based on a similar construction. A fluid product is pumped through a tube surrounded by a jacket through which a refrigerant is passed. The fluid freezes on the surface of the tube, but a rotating shaft with scraping blades inside the tube continually cleans the frozen film from the tube and mixes it into the stream of product. The final temperature can be consistently controlled by regulating the speed of the pump and the flow of refrigerant through the jacket. The small volume of product flowing between the tube and shaft surfaces can be rapidly cooled (or heated), compared to processing in less efficient batch vessels. This gives a very consistent and generally a superior texture and taste compared to the batch products, where some portions are overcooled (or overcooked).

Ice cream made this way in a Vogt Freezer is very smooth and creamy, because the ice crystals are extremely small. The ice cream exits the Vogt Freezer only partially frozen, so that it can be filled into tubs or other containers without trapping air pockets. These containers are then moved through freezing tunnels or to cold storage spaces where final freezing takes place. Ice cream in this type of packaging is scooped out into cups or cones for consumption. Clarence Vogt also developed the MelORol process for Borden’s in the 1930s, where the ice cream was more completely frozen and discharged from a pipe in a long cylinder that was wrapped with paper and then sliced into serving sizes. The MelORol packaging is no longer produced, but many Vogt Freezers built by Cherry-Burrell are still in production to this day. Competing freezers based on the same principles are now made by several companies, but the Vogt Freezer was for many years the only machine of its type.

The fats and oils industry was another area ripe for improvement at this time. Lard and vegetable shortening was produced by freezing a thin layer of the molten fat on the surface of a “chilling roll”, a rotating drum with ammonia refrigerant on the inside. A blade scraped the frozen film off the drum, dropping it into a trough with an agitator often called a “picker box”. The agitator kept the fat crystal structure “plastic” and scoopable rather than firm, and it also blended in some air to make it whiter in color and easier to incorporate into dough or other food products. This method was not very energy efficient, the product was exposed to the atmosphere and contaminants, and air incorporation promoted rancidity through reaction with oxygen in the atmosphere.

The “Votator process” for making these kinds of products allows for rapid cooling of the molten fat in the Votator scraped surface heat exchanger, so that many, tiny crystals are formed. Nitrogen gas can be injected along with the molten fat, to be whipped in under pressure and in a closed system. This way no oxygen is introduced and the shelf-life of the product is extended. After cooling in the Votator heat exchanger, the product finishes crystallizing in a secondary machine, the Agitated Holding Unit, which agitates it to make it soft and plastic. This is how lard, shortening, and soft tub margarine are made today. If a firm consistency is desired, as for stick margarine, the crystallization takes place in a holding tube without agitation so that the crystals grow together.

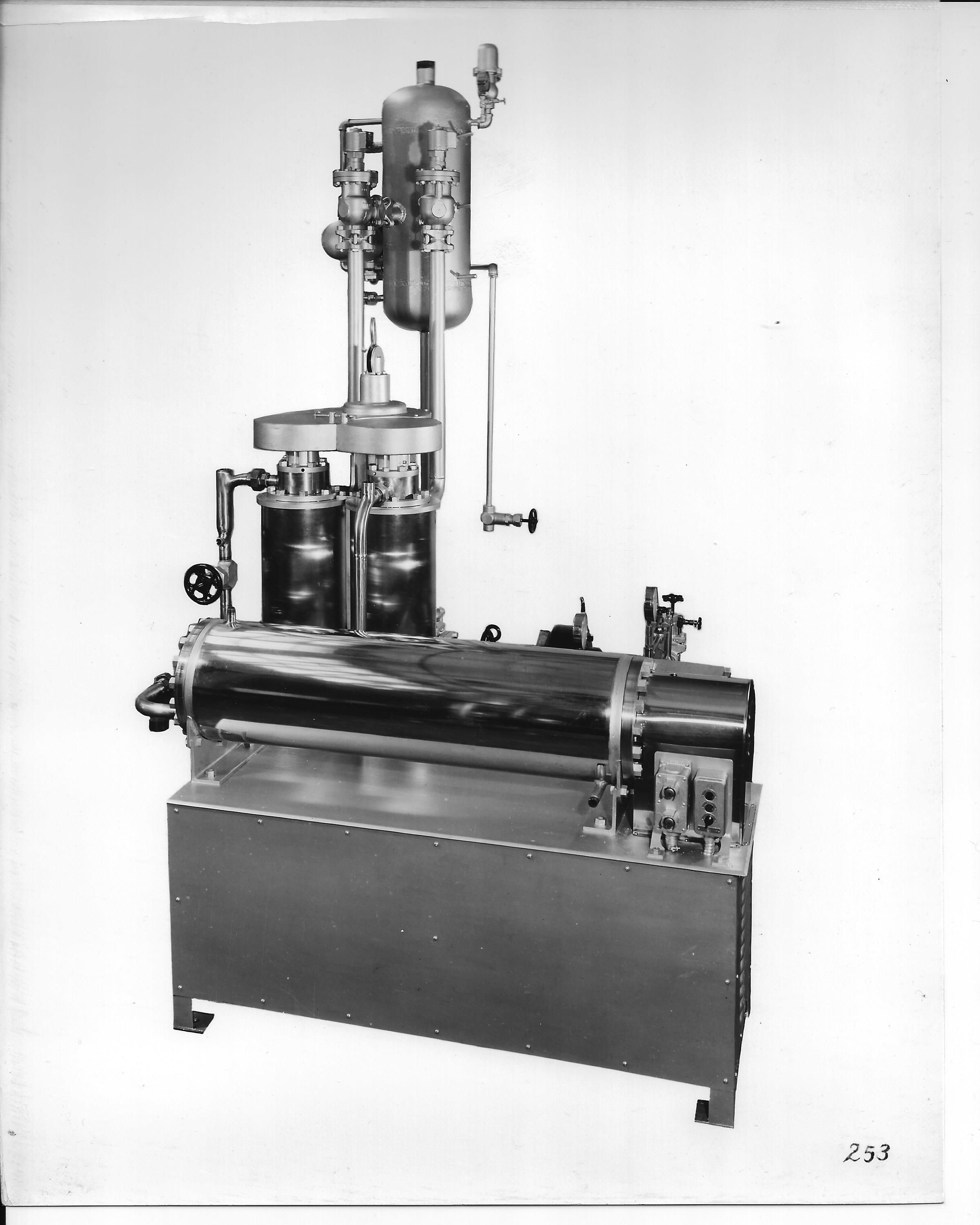

Lard and shortening processes using the Votator were introduced about the same time as the Vogt Freezer, and the first commercial Votator margarine process was installed in 1936. In this photo a small installation is shown that may have been a demonstration model for pilot testing in a customer plant. The Votator heat exchanger and refrigerant controls are at the far right, with the feed pump next and the agitated holding unit to its left. Last on the left is a manual fill station where cans or pails can be filled to a standard weight. A gas cylinder for supplying nitrogen can be seen behind the line.

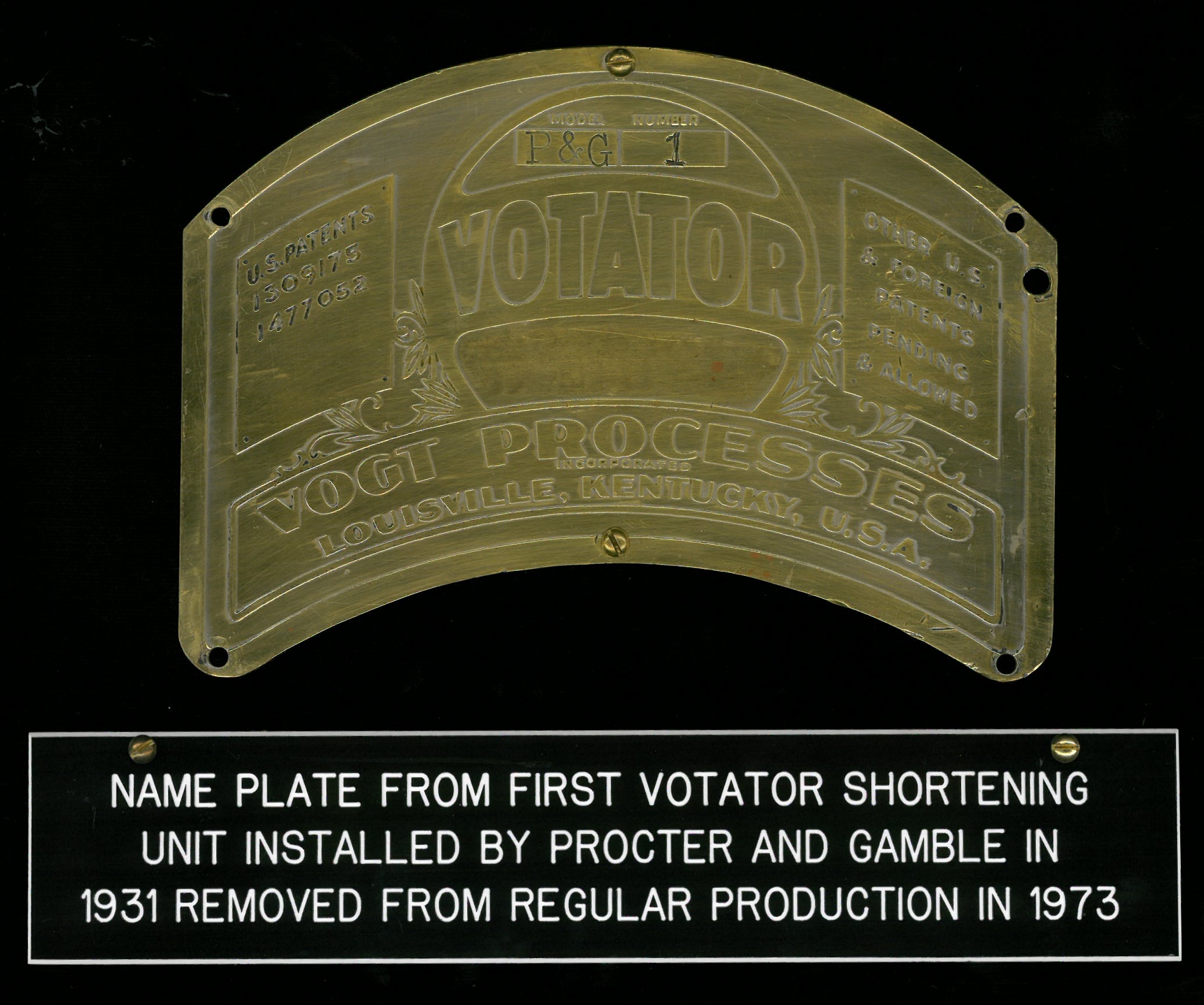

The original business model was to lease the equipment and collect a toll based on production volumes. In a 1934 interview Clarence Vogt estimated that he made $1,000 per day from the MelORol invention, for example. Procter & Gamble chose to own the equipment for producing Crisco shortening, however, so the first two Votator shortening systems at their Cincinnati factory were purchased outright. These Votator units provided over 40 years of service before they were finally decommissioned, as the plaque below containing one of the original brass nameplates declares.

These earliest machines had both the Votator scraped surface heat exchangers and the agitated holding unit mounted in a common cabinet, as shown below.

Later configurations changed the layout of the Votator system as more experience was gained. The Votator heat exchangers are mounted in a vertical orientation in the very compact system below, which likely processed 7,000 pounds per hour of lard or shortening using ammonia refrigeration.

By 1964, over 90{e5db15d02c984ae3069909e2f0b0fd04a63d07514f3185dfbb3c24698957a124} of the lard, shortening and margarine production in the United States had converted from the use of chilling rolls to the Votator process [Bailey’s Industrial Oil and Fat Products, 3rd Edition, 1964]. These early successes in the fats and oils industry laid the foundation for ongoing research exploiting the many principles and benefits outlined so clearly by Clarence Vogt. This has produced many new applications in the 85 years that have passed, bringing modern, continuous processing to the food industry with excellent quality and consistency.

Notable food applications include: cooling peanut butter prior to packaging; cooking flour-sugar slurries to make extruded licorice; crystallizing sugar and fat in icings; and heating and cooling puddings, cheese sauce, fruit and vegetable purees and concentrates for sterile, aseptic packaging with a 1-year, non-refrigerated shelf life. For the meat industry, the Votator is used to cool deboned chicken emulsions, to heat sausage blends, and to cool offal from packing houses for use in pet food. Industrial uses include cooling automotive greases and silicone caulk, crystallizing or gelling stick deodorant prior to packaging, and crystallizing wax for candles and for incorporation in printing ink. For many of these products, a scraped surface heat exchanger, like the Votator, is the only practical method to efficiently and economically process them to achieve the highest quality and consistency, day-in and day-out.

* * * * *

“A preferred method of forming the beta-phase plastic shortening of this invention comprises forming a completely melted mixture of the base stock-and hard stock in the above described proportions. This generally can be accomplished by heating to a temperature in excess of about 150 F. The melted oil mixture then is pumped through a scraped wall heat exchanger in which the oil is rapidly chilled to a temperature of from about 70 to about F. A suitable device for this purpose, referred to as a freezer or Votator, is described in US. Reissue Patent No. 21,406, granted to Clarence W. Vogt, March 19, 1940. From this heat exchanger, the chilled super-cooled mixture is pumped into containers where the shortening substantially completes its crystallization. Transformation or the shortening solids to beta-phase then takes place at rest in a tempering room which is held at a temperature of from about to about F. Within a period of about 12 hours after the shortening reaches 110 F., its crystalline structure is converted to predominantly beta-phase crystals. That is, both the beta-phase-tending and non-beta-phase-tending solids will be converted to predominantly beta-phase crystals (70{e5db15d02c984ae3069909e2f0b0fd04a63d07514f3185dfbb3c24698957a124} or greater). Shortening prepared in the above manner will be plastic and have a substantial interlacing of-crystalline particles of very small size.” –

https://www.google.com/patents/US3194666

SOURCE: – Read entire story here.