Much of my education in woodworking has been from what I describe as the relentless push to fail. That is, coming up with an objective that pushes the limits of what I can do, what I feel is possible, or what is possible. I came up with the objective to tie a knot in a piece of wood about ten years ago and I now feel that I have succeeded.

September 2016

My first attempt was in September 2016. My wife and I were at home anticipating an imminent trip to the hospital for the birth of our first son, and were just trying to stay busy while not starting any projects that could not be completed or abandoned in a few minutes.

Much of my education in woodworking has been from what I describe as the relentless push to fail. That is, coming up with an objective that pushes the limits of what I can do, what I feel is possible, or what is possible. I came up with the objective to tie a knot in a piece of wood about ten years ago and I now feel that I have succeeded.

September 2016

My first attempt was in September 2016. My wife and I were at home anticipating an imminent trip to the hospital for the birth of our first son, and were just trying to stay busy while not starting any projects that could not be completed or abandoned in a few minutes.

I picked through some air-dried ash for the straightest grain and ripped a handful of 1/4″ square strips. I cut them 10 inches long and proceeded to steam them in the kitchen using a large frying pan and sheet pan on the stovetop. Using my hands, I carefully began to bend the wood into a loop before coaxing one end through the loop. When the wood became too dry or cool, I returned it to the pan to steam more before squeezing the knot tighter.

There were certainly some failures where many of the wood fibres broke before bending enough to form into even a loose knot. There were a few moderate, encouraging successes, where I was able to form a knot about 2″ diameter with some fibre breakage.

May 2018

The next time I attempted a knot was before the birth of my second son. This time, I was armed with a compression bending jig to help bend the wood, made from a few scraps and an old hacksaw blade. The ideas is that the flexible metal compression strap (hacksaw blade) and attached stops keep the outside of the wood from expanding and splitting as the wood is forced around a form. In fact, since the length of the wood is matched to the space between the stops, the wood is not only held in compression during the bend, but compressed in length!

For a form, I used a piece of 6″ wide plywood with a 3″ radius cut at one end. Again, I cut and steamed my 1/4″ square air-dried ash strips, then quickly moved them, one at a time, to the bending jig and pulled the wood around the corner. I rotated the wood 180 degrees and bent it again, then turned it 90 and 180 degrees to bend it the other two directions. Some say that steaming and bending wood in all four directions effectively destroys the lignin bonds, allowing wood to be manipulated with extreme bends and even twists.

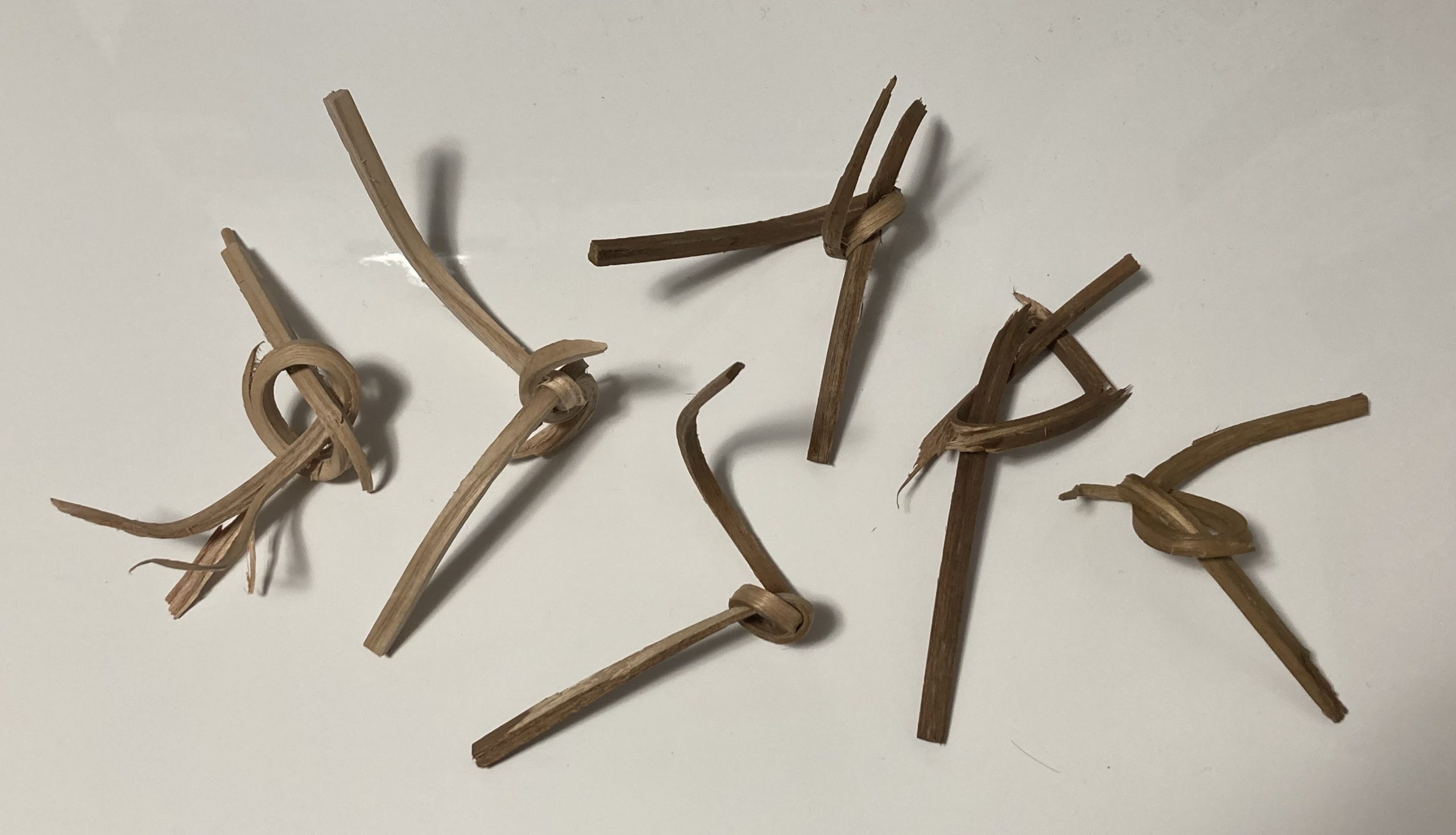

After using the compression jig to bend each piece of wood all four directions, they went back in the pan to steam before attempting to form them into knots by hand. There were still some failures where too many wood fibres broke, but I got two knots down to 1-1/2″ diameter with a medium amount of fibre breakage, and 1-1/4″ diameter with considerable fibre breakage. Despite the fibre breakage, I felt these two examples were indicative of significant progress.

July 2022

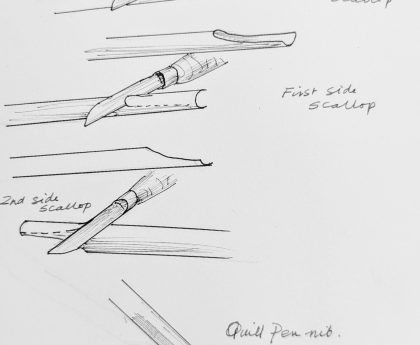

Last month, armed with some new and modified techniques, I once again prepped to attempt tying knots. For materials, I chose straight-grained air-dried black locust (I had some 5/4 scraps lying around the shop, but no ash). Instead of sawing blanks, I instead used a hatchet to split out some pieces about 1/2″ square, then ripped them to about 1/4″ with the bandsaw and finished planing them to 0.2″ with a hand plane with depth skids attached.

I reworked my compression bending jig by reducing the radius of the form from 3″ to about 1-1/2″ and positioning the end of the compression strap 0.2″ from the form. Due to the length of the strap compared to the radius of the form, the compression strap needed to make a 270 degree corner and a smaller radius would have required some sort of helical bend of which I was reluctant to try. (I also built a linear compression jig to compress the wood in a straight line by about 3/4″ using a screw press, but the method ended up being too slow and impractical to use so I abandoned it).

This time I pre-soaked the wood to ensure the wood was well saturated. The wood was put in a pan filled with water and soaked for about 1-3 weeks as I made attempts on three separate occasions for this round. The actual streaming was a two-step procedure this time. I first steamed the blanks in my largest fry pan with a sheet pan for a lid for about 15 minutes before bending each in the compression bending jig all four directions, one at a time.

Then I fit the bent wood into a smaller pan with a proper-fitting lid to better control the steam and let it steam for another 15 minutes. I used my hands to form loose knots, returned then to the pan for 15 minutes, then proceeded to tighten the knots. I used a small wooden handscrew clamp to tighten some knots and hold them in position while they cooled.

Again, I had a few catastrophic bending failures where over half of the wood fibres broke. But yesterday I also had one very good result with a 7/8” diameter body that makes me comfortable saying that I’ve achieved my objective.

Here’s what I learned from tying knots in wood:

- Split wood is a must. If you don’t split it before, it will certainly split during extreme bends. Even my split wood split more during bends.

- For a knot of this scale, 1/4” square stock is huge and square doesn’t really make sense. My best knot was formed from a piece of quartersawn black locust about 3/32” thick and 0.2” wide.

- The bending jig with compression strap was a great asset. Using a radius as tight as possible further helped. I could have improved the jig by adding an adjustment for one of the stops so a piece of wood already bent and compressed by about 0.18” could be bent and compressed further.

- Wood bends best when wet and hot. Some of my steaming setups allowed too much steam to escape and when I took out a piece of wood, it wasn’t very hot or wet. A tight-fitting lid on the pan helped.

Our daughter was born last Wednesday. We have no plans for any more children and I have no desire to advance my knot tying skills in wood any further.