When gluing up edge joints, you want to maintain proper alignment of the boards to produce a flat panel. Especially for small shop woodworkers, it takes a lot of work to flatten glued up panels, which accounts for the proliferation of specialized clamps and devices designed to keep the boards aligned during glue up. Maintaining alignment The simplest reliably effective answer is a tool you probably already own: the biscuit joiner. Start with flat boards and good edge joints. Place #20, #10, or #0 biscuits typically 8-12″ apart and just a couple of inches or so from the ends. Remember to account for the trim allowance so you do not leave an exposed biscuit in a tabletop. The most consistent…

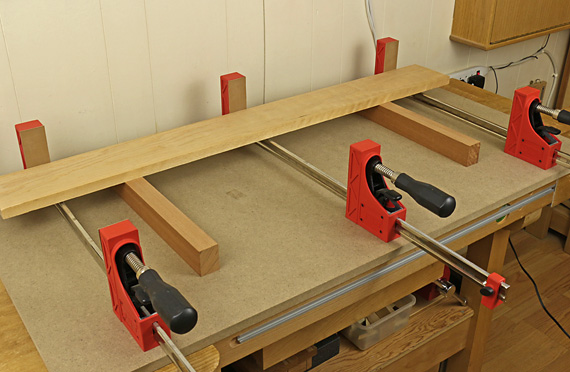

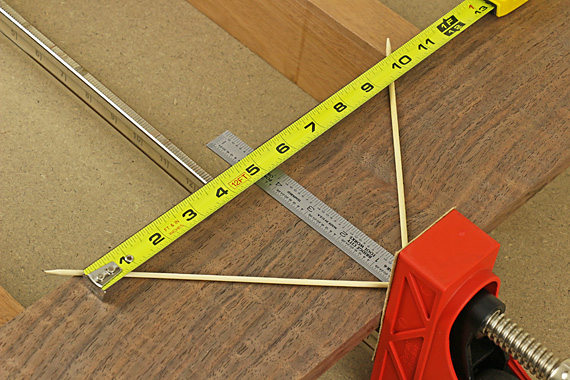

Clamp setups The most important step in a trouble-free clamping regimen for edge joints is to get a set of parallel-head clamps, such as those made by Jet and by Bessey. These invaluable tools eliminate most problems. It is best to do the glue up on a flat base such as a workbench with a sheet of 3/4″ MDF on top or a dedicated assembly table. You then want to transfer that flatness to the panel to be glued. The best and most versatile method, especially useful for gluing up long boards, is to rip two thick boards to the same width and set them on the work surface parallel to the clamp bars where they will act…

Clamping capacity Can small shop clamping methods generate enough pressure to make a good edge-to-edge joint? The short answer is yes. Let’s look at the details. The US Forest Products Laboratory in their very useful Wood Handbook, chapter 10, page 16 (2010 edition), recommends pressures of 100 pounds per square inch for low-density wood and up to 247 psi for the highest density woods. The book also states: “Small areas of flat, well-planed surfaces can be bonded satisfactorily at lower pressures.” Jet claims (I suspect rather conservatively) 1000 pounds of force can be generated by their parallel-head clamps while Bessey claims 1500 lbs. for their similar K Body Revo clamps. As an example, 1500 pounds of force produces 200 psi…

This discussion primarily applies to PVA glue, which most woodworkers use for these joints. I prefer Titebond III for its relatively long open time, ease of use, and dependability. Alternative glues with longer open times include special slow-set PVAs or liquid hide glue. The gluing process Speed is paramount. It is absolutely imperative that the thin layer of glue not start to skin over or stiffen. This can result in a weakened joint and/or a glue line that is too thick. I suspect this is one of the main causes of failed edge joints and cosmetically poor joints. A good glue up requires a rehearsal – it is worth the time. Dry clamp the boards, working out clamp…

When to remove the clamps The instructions on the Titebond III bottle recommend “clamp for a minimum of 30 minutes (longer is better)” and “Do not stress joints for 24 hours,” which is how long PVA glues generally take to fully cure. I leave the clamps on at least overnight. There really is no hurry to remove them unless they are needed for other work. Furthermore, I will not be working the board for at least 24 hours to allow time for the joint to condition and the board to reach a uniform moisture content as excess moisture exits the glue line area. This avoids producing a sunken joint line or depressions over the biscuits when surfacing the panel. Also…