The primary function of a table saw riving knife and a splitter is to prevent kickback and maintain control over the workpiece. Positioned behind the blade, they prevent the saw kerf from closing in on the blade, which can lead to kickback. When the workpiece contacts the back of the blade, the rotating teeth can grab it and propel it back towards you, a dangerous occurrence known as kickback.

However, there is a significant difference in how a splitter and a riving knife operate.

A splitter, also known as a spreader, is a thin vertical piece of metal positioned behind the saw blade, similar to a riving knife. However, unlike a riving knife, a splitter is often fixed in place and does not move up and down with the blade. It serves a similar purpose in preventing kickback by keeping the kerf open and the cut material from pinching the blade.

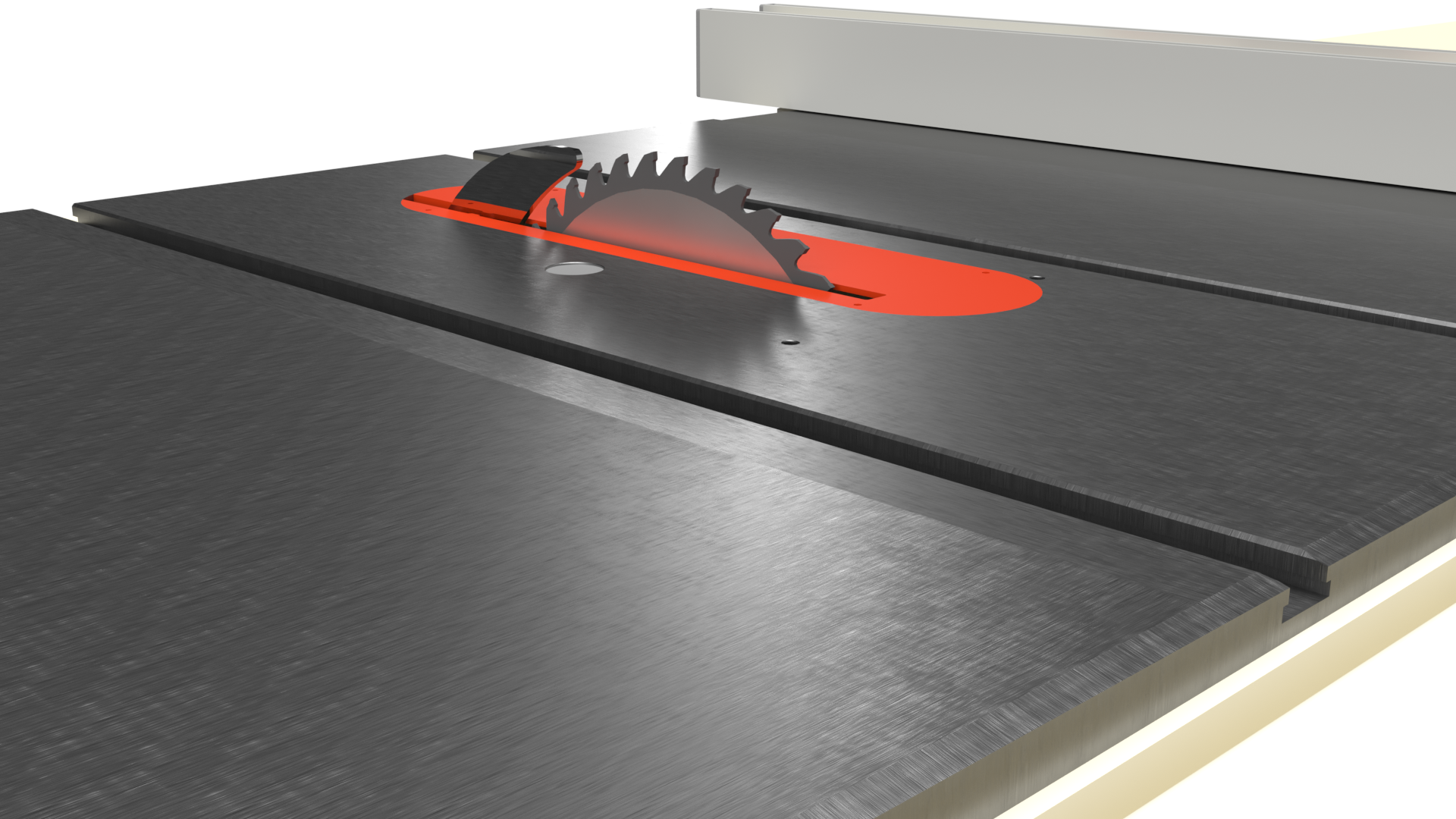

A riving knife is a thin metal blade that sits behind the saw blade, maintaining a consistent distance from it. Its primary purpose is to prevent the cut material from closing in on the back of the saw blade, which can cause kickback. The riving knife keeps the kerf (cut) open as the workpiece passes, ensuring a smooth and safe cut. Since the riving knife moves up and down with the blade, it remains in the same position relative to the blade throughout the cut. Keeping it the same distance also prevents small pieces from falling behind the blad, turning them into missiles, and being thrown back at you. This is in contrast to a splitter that stays fixed in one place, and as you lower the blade, the gap between the splitter and blade increases, creating room for small workpieces to come in contact with the back of the blade.

Another advantage of the riving knife moving with the sawblade is that if you want to make a shallow kerf cut such as a dado, the workpiece can pass over the riving knife while the knife is still allowed to do its job. A splitter has to be removed on shallow kerf cuts that do not cut all the way through the wood, as the wood will hit the splitter, preventing it from passing by. So, if using a splitter for these types of cuts, you will have to remove it.

Not having to remove the riving knife for most operations has the benefit of protecting you from complacency. Re-installing a splitter takes time and is a pain in the butt, so many tables saw users opt to leave it off, which can create safety hazards for future cuts.

If your table saw did not come with a riving knife, but you still want similar safety advantages without the hassle of uninstalling and re-installing splitters, there is a third option. You can cut a kerf in your zero clearance insert and glue a piece of wood in the kerf to act as a riving knife/splitter. There are commercially available after-market splitters if you don’t want to make your own.

While both devices serve the same safety purpose, riving knives are generally preferred because they offer more consistent protection throughout the cut since they move with the blade. Many modern table saws are equipped with riving knives due to their superior safety and functionality compared to splitters.