The first step of making the Berger Board

is to fabricate the two (2) torsion boxes needed for the bent laminated glue

up. I made my torsion boxes from plywood and pine.

is to fabricate the two (2) torsion boxes needed for the bent laminated glue

up. I made my torsion boxes from plywood and pine.

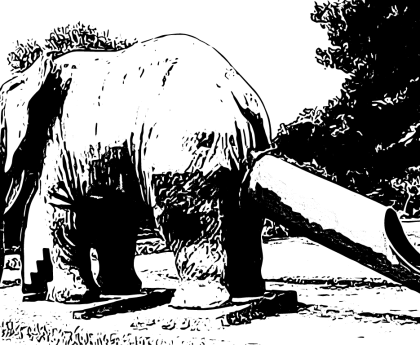

| All torsion boxed up and nowhere to go. |

The type of plywood isn’t really

important. I bought the 2’ x 4’ ¾” & ½” “sanded” plywood from Lowes. What

is important is that the plywood is flat. Take your time and select the flattest sheets they have.

important. I bought the 2’ x 4’ ¾” & ½” “sanded” plywood from Lowes. What

is important is that the plywood is flat. Take your time and select the flattest sheets they have.

I used clear pine for the ribs. Again, be

careful to choose the flattest and truest boards you can.

careful to choose the flattest and truest boards you can.

After milling the boards to 4S I trimmed

the plywood to size. Then I assembled to two (2) torsion boxes using my table

saw as a flat reference surface.

the plywood to size. Then I assembled to two (2) torsion boxes using my table

saw as a flat reference surface.

I then took additional pieces of the pine

which I had also milled square and added a fence and riser block to the bottom

(larger) torsion box. These will provide a surface to clamp against and create

the lift in the tail needed for the proper Berger Board glue up.

which I had also milled square and added a fence and riser block to the bottom

(larger) torsion box. These will provide a surface to clamp against and create

the lift in the tail needed for the proper Berger Board glue up.

The final steps of the Torsion Box

construction allowed for an easier glue up. I covered the inside faces with

packing tape in order to prevent glue stick. Then I added feet to the bottom

torsion box in order to allow the clamps to fit below.

construction allowed for an easier glue up. I covered the inside faces with

packing tape in order to prevent glue stick. Then I added feet to the bottom

torsion box in order to allow the clamps to fit below.

As silly as it may sound, I find building torsion

boxes fun, as there is something satisfying about the rigidity of one which is

properly constructed.

boxes fun, as there is something satisfying about the rigidity of one which is

properly constructed.

Don’t forget about the +Modern Woodworkers Association Podcast. We talk woodworking with Guests from around the world of woodworking every other week. Subscribe to the RSS feed or iTunes today.