When creating a PCB to get made by a 3rd party you need to generate some files to send. There is a industry “standard” called the Gerber format or more commonly Gerber files. Most PCB software can generate these and many can also view them. There can be subtle differentiations between each manufacturer, often around the naming of files and the sizes of the tracks and drill holes supported. Small changes to your files can also make a big difference to the final price if a non-standard process is required.

KiCAD

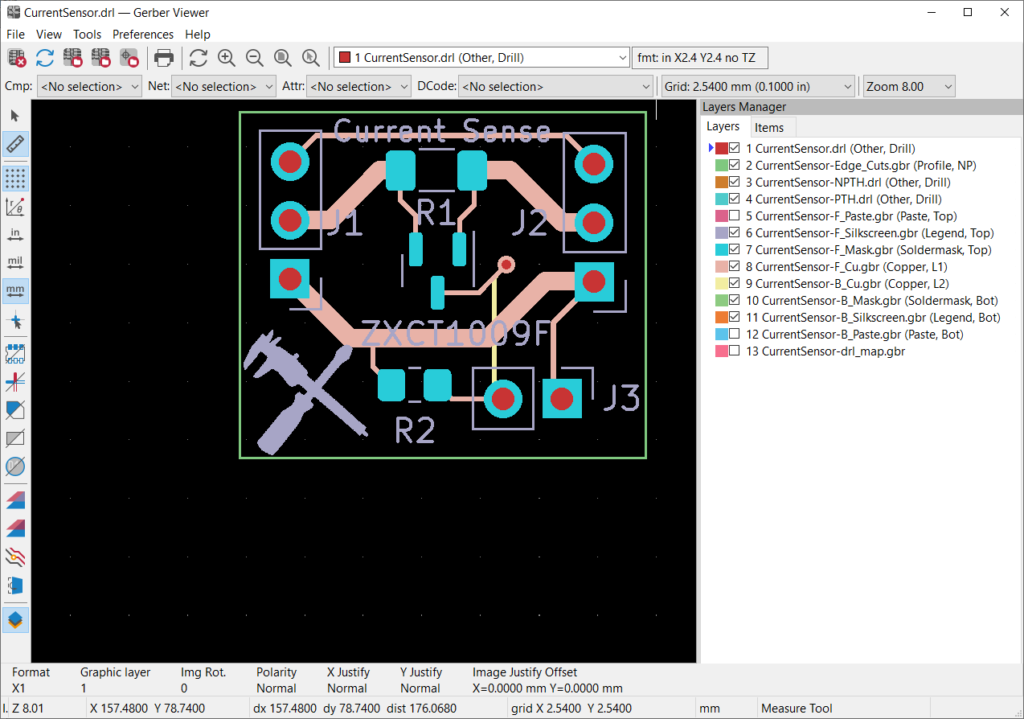

I’m a big fan of KiCAD for designing my boards, it can generate Gerber files but it can also view them. Which is a good way to check your files before sending them to make sure you’ve got all the labels in the right places and have not missed any components. I also like to use the 3D viewer which can really help if you’ve got large or odd shaped components like switches, sockets or relays. But it does depend on the components having models. See kicad-footprints for details of how I made a 3D model and footprint for some simple components.

Manufacturer’s viewers

If you are getting the boards sent off for manufacturing then it is worth while looking at the boards in the manufacturers viewers. The might show issues such as the silk screen being cut off as it is too close to the edge of the board.

It is always worth checking with the reports generated by these viewers too. These can be shown as “Design for Manufacture” checks or simply recommendations.

Following the recommendations might not always be necessary but will definitely make for more reliable board manufacture which will be important if you are making lots of boards. Other issues I’ve spotted with these viewers are problems with fonts not appearing as expected. Most have the ability to check different layers independently and some have extra features such as 3D viewers, rulers and zooming.

Most of the manufacturers allow your to use their viewer for free as it’s a good way to funnel you into their sales process.

The viewers are not a 100% reflection of how the boards will turn out but they are getting better all of the time and are an great additional tool to help you ensure your boards are turn out right.

Posted in:

Posted in: