Clamping capacity

Can small shop clamping methods generate enough pressure to make a good edge-to-edge joint? The short answer is yes. Let’s look at the details.

The US Forest Products Laboratory in their very useful Wood Handbook, chapter 10, page 16 (2010 edition), recommends pressures of 100 pounds per square inch for low-density wood and up to 247 psi for the highest density woods. The book also states: “Small areas of flat, well-planed surfaces can be bonded satisfactorily at lower pressures.”

Jet claims (I suspect rather conservatively) 1000 pounds of force can be generated by their parallel-head clamps while Bessey claims 1500 lbs. for their similar K Body Revo clamps. As an example, 1500 pounds of force produces 200 psi over a 10″ length of 3/4″-wide glue line (7.5 square inches area).

So yes, adequate pressures can be generated in the small woodshop. There’s no need to get out the calculator, just lean toward more clamps and more torque with denser species/thicker boards and less beef with less dense species/thinner boards. And, of course, make good joints.

Clamp spacing

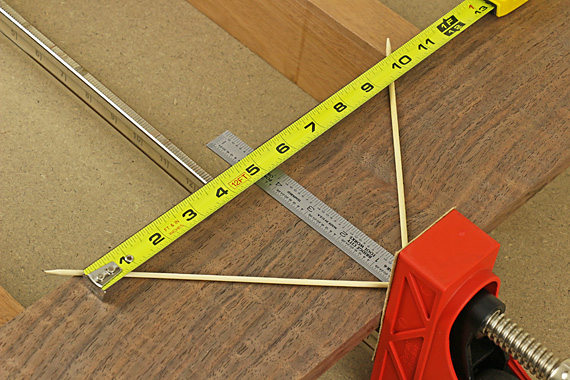

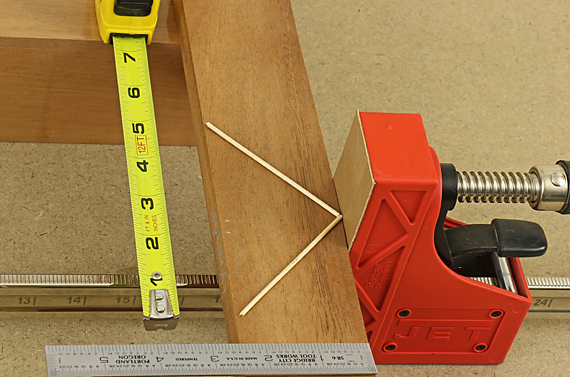

How about spacing the clamps? This depends partly on the above issue but also on the mechanics of the force spread. Even a wanabe engineer like me can surmise that the board is acting as its own caul and thus the transmission of force to the glue line depends on the width and stiffness of the board. I long ago adopted, with consistent practical success, Ian Kirby’s rule that the clamp force can be assumed to spread in a 45° fan.

Thus, referring to the diagrammatic photos herein, the maximum distance between clamps (remember, there will be clamps above and below the panel) should be twice the width of the narrower of the two outer boards in the panel. Shown at top, the 5″-wide board requires fewer clamps (maximum 10″ apart), than the 2 1/2″-wide board below (maximum 5″ apart), if all else is equal.

Assembly

Regarding assembly, I first moderately tighten the center clamp, and then work outward, avoiding heavy pressure. Then I add the upper gang of clamps, moderately tighten them, check with a straightedge for problems, and make any needed adjustments. Then I torque down everything, and check/adjust again. All of this is done very quickly!

Accordingly, I glue up any panel with more than three boards in separate sections, and usually prefer to limit the sections to only two boards, especially if the intermediate panel can fit in my jointer-planer. This is wood – nothing is perfect all the time. I’m usually working with very expensive stock and like to preserve the opportunity to reset any errors rather than let them accumulate.

Next: Glue issues.

SOURCE: Heartwood – Read entire story here.