When you find a good supplier for your wood it’s worth a strong relationship with them. As it is with many things, the choices of suppliers lessen with each year and with that comes the inevitable increase in prices. A good supplier deserves good support even if we do have to pay more. I bought £650 worth of wood this week but it’s enough for about four good-sized projects. My plans include a shelving unit, a dressing/desk table and an end-of-bed, lift-up lid chest. For these pieces, I am including some unusual use of plywood panelling which will add another £400 so I am looking at £1,000 for these three units plus my fourth and current project now where I am making a compact unit we might at one time have known as a linen press or an armoire.

My oak is what the company I buy from refer to as premium oak. These are shorts at 7’0″ long and the widths vary from 4-8″ wide. The thickness is consistent at 1 3/32″ (27-28mm). Mostly they are quarter-sawn with more or less medullary rays evident in the face figuring but all of the pieces I look for are still within the acceptable quarter-sawn angle (60-90º) and that gives me better stability with less of the cupping and twisting I might normally associate with flatsawn and wider boards. This means less work in stock prep, which is a bonus for a hand toolist bringing the stock into shape using only hand tools and possibly a bandsaw. Only in hand tool handworking do we use every muscle and sinew to work our wood. Otherwise, we stand at the infeed end and simply feed the wood through and and then wait ot the outfeed to catch and feed it either back through or feed it in again for an adjacent opposite cut. Not much exercise at all, knees locked, arms folded and such, a little walk between action now and then.

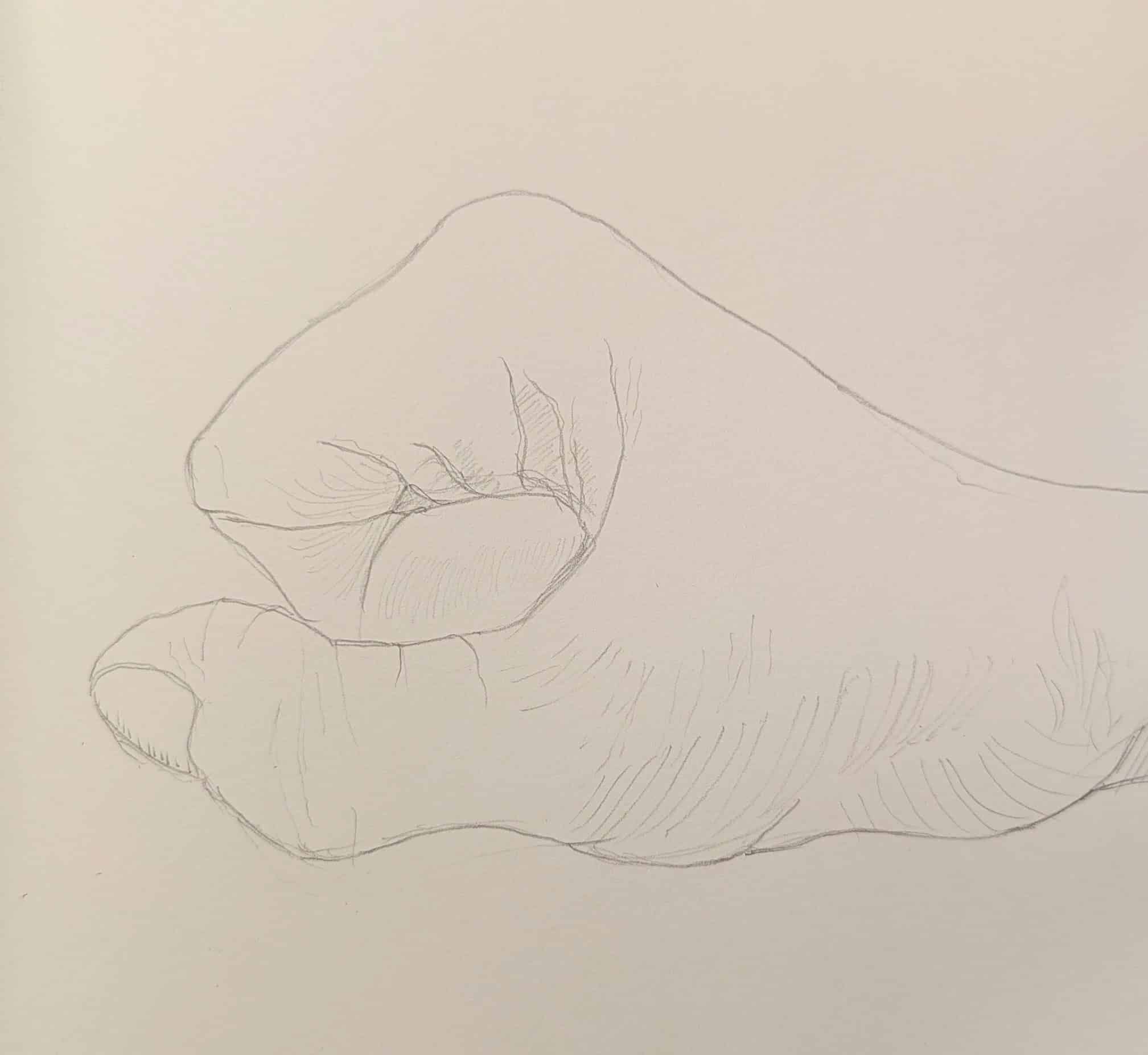

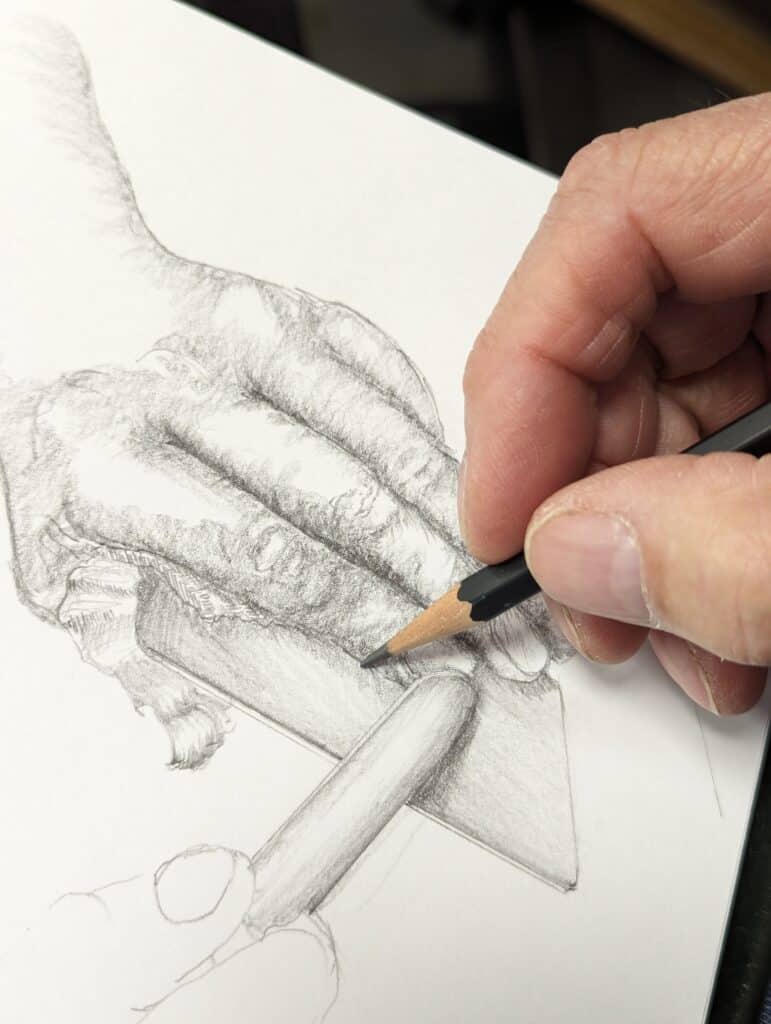

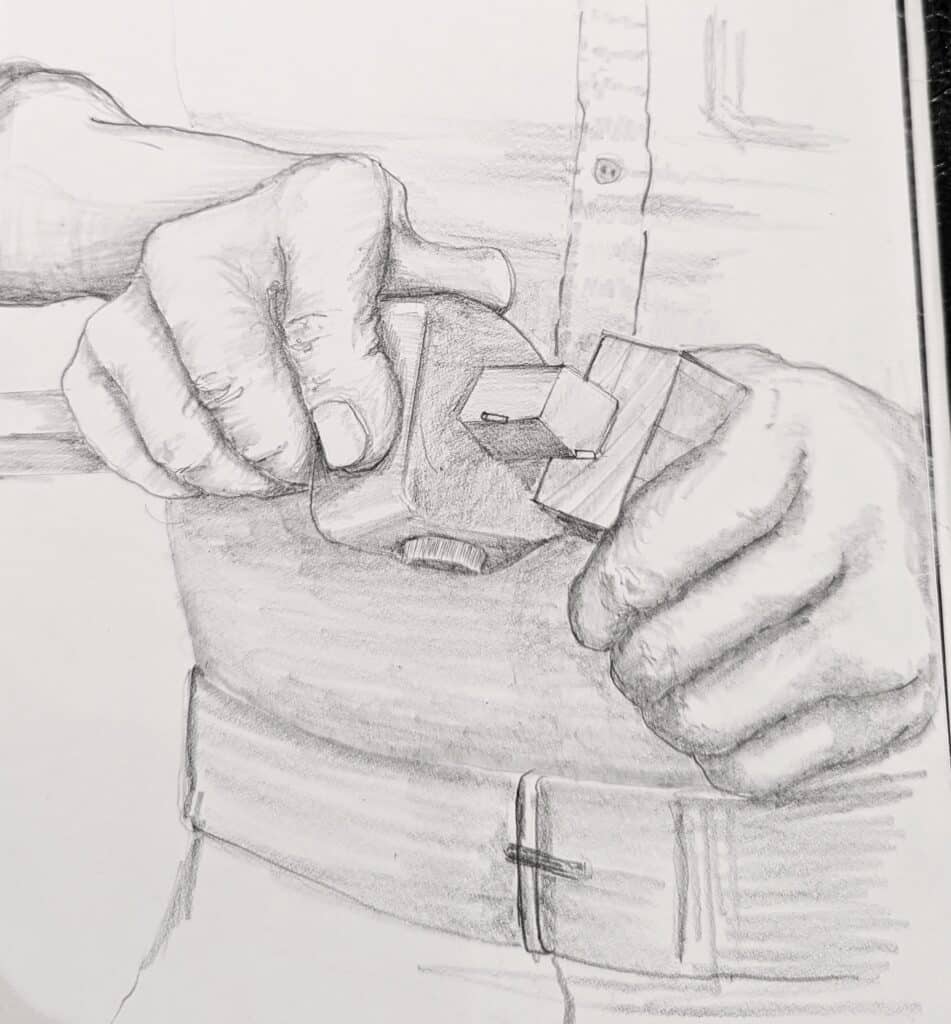

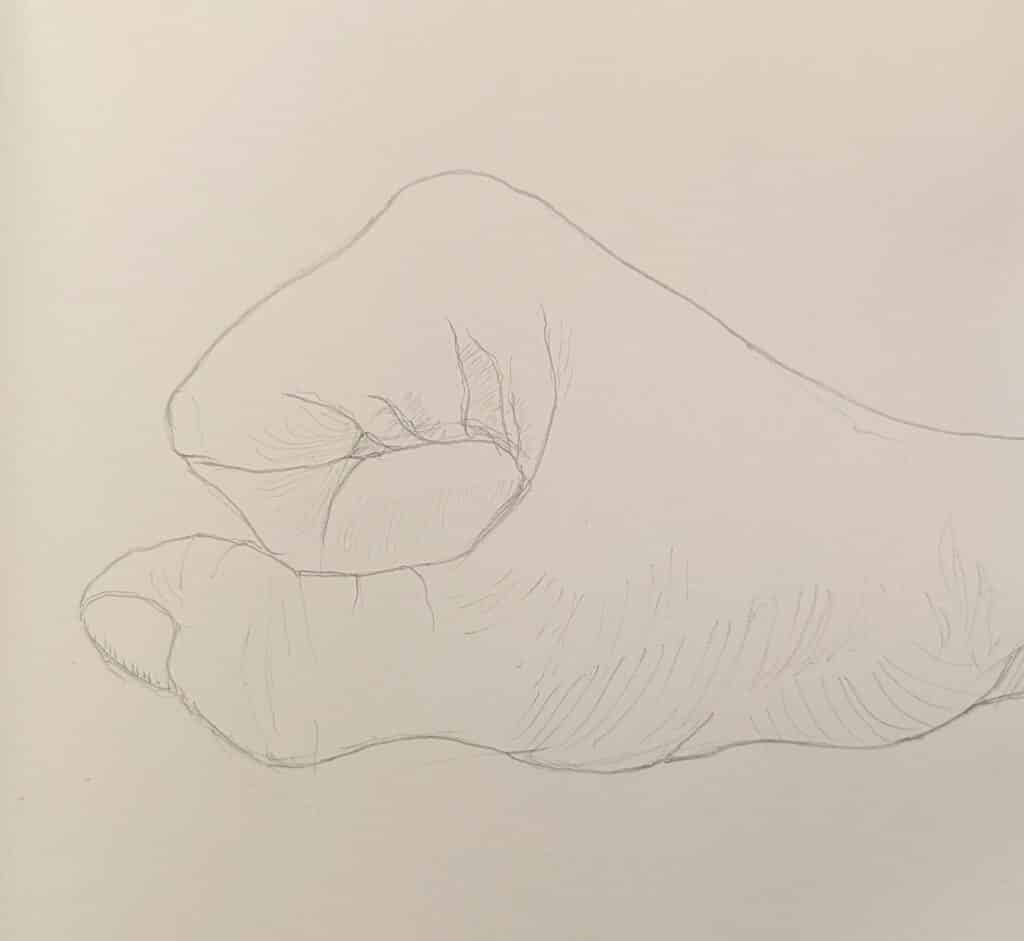

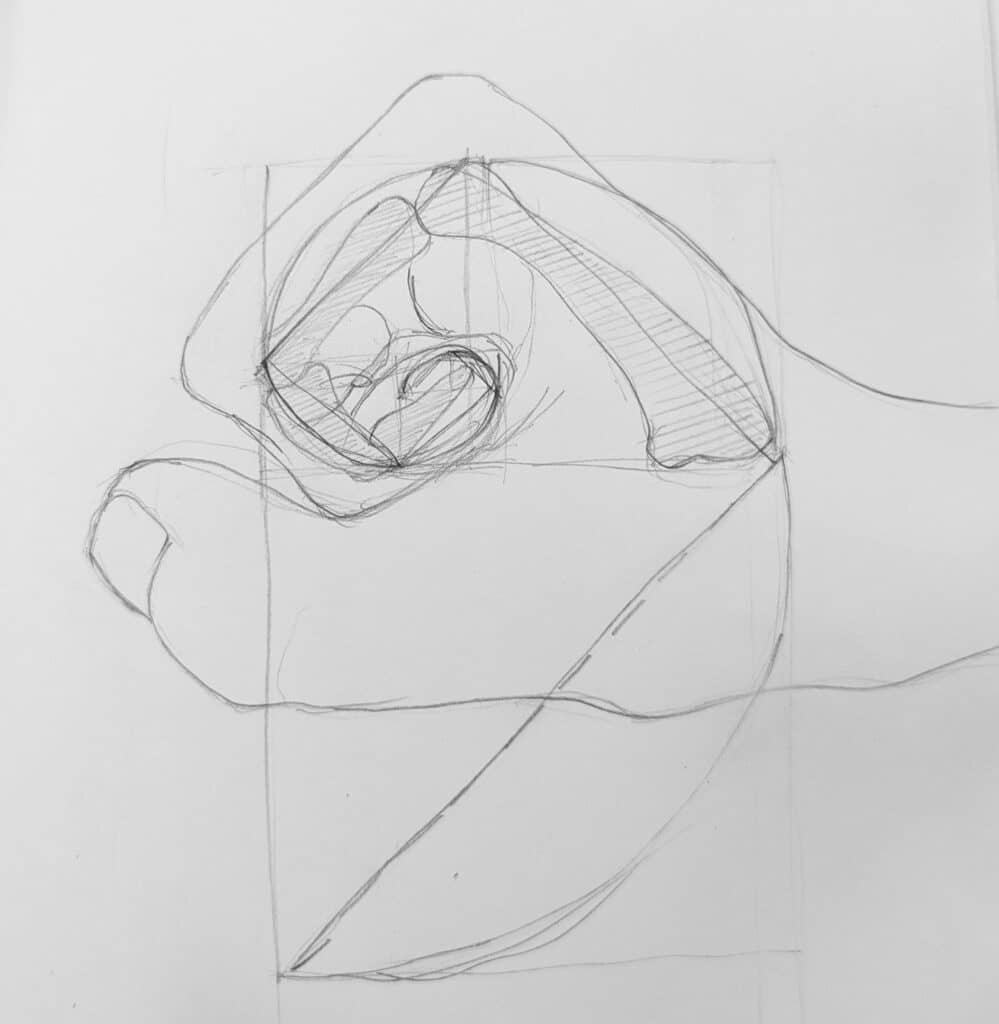

I study hands from watching the hands of others but it’s getting harder to find these ‘others‘ these days. Actually, I can’t really find them any more. Only Hannah, who’s worked with me for almost a decade now really uses hand tools for all her work. `Ever since I was a young apprentice I have been fascinated by the working hands of those relying on their own two hands to make be they seamstresses, woodworkers, blacksmiths or whatever. Who do you know that makes any more for a living as a maker in handwork? I always try to catch movements, grips, twists, stretches and so on at my graphite tip on paper. It’s a fascinating thing when you think that there are 27 bones in each of our hands and that’s 25% of all the bones in our body.

Imagine these all intricately and inextricably woven together in our mother’s womb and now full-grown and fully linked by ligaments aided by muscle attached to bone by tendons to conform to just about any task we put our hands to. Imagine this though, we talk about clicking on and following this or that link these days but they have nothing to do with the links that perform millions of tasks large and small in the everyday use of our human body. It’s easy to take the commonplace for granted and yet without them, we would be utterly lost in all that we do. Imagine the devising of such an amazing linkage capably performing all the tasks we ask of them by a chemical sending signals through our synapses in split seconds to each hand as we work through tasks in the every day. The other thing is this: they never refuse what we ask of them and neither does the left hand say no to the right. What a partnership! Here we have the unique transmission of electric nerve impulses between nerve cells (neurons) or neurons and glands and muscle cells. These synaptic connections, neuromuscular junctions keep our bodies working in the day-to-day and mostly we ignore them.

I picked out my wood with Hannah, flipped each oak board to find what we wanted, and made minute-by-minute decisions to accept one board over another and then reject another, which meant agreement at both ends of the boards. This too is a synchrony established through working together and a willingness to interact. I have worked with others who never worked as one and always twisted the board the wrong way. These are the difficult people you sometimes, maybe often, have to work with at different times in your life. Hannah and I advantaged each other by the twisting of one end to be grabbed by the other and that, I realised, comes after eight years of working alongside one another where there is an unspoken agreement through understanding what we are considering, yes, but also how we are considering.

Fibonacci sequence, Archimedes spiral, whatever you want to call it, is highly evident in the human hand almost more than anywhere else and yet we may not even notice it. Go ahead. Close your fist and look at it sideways. Unfold your hand slowly from the clenched fist and be amazed by this simple unfolding. Now think of what just happened in your brain by this simple doing.

In picking this oak I know that I can get a consistent 7/8″ thickness for my project after my hand planing and truing, thicknessing to equal parallelity and such. I can even get some pieces to finish out at 1″ quite well and that is just by using quarter-sawn. This reality is very helpful to us as individual, small-scale makers making and selling one piece at a time or working on a small batch production now and then; that’s us as the ones working in our own garage space on a more domestic scale.

Ninety-nine per cent of choosing takes place in the first glance of a board. You can identify almost every issue in a plank without touching it or flipping it as issues on one side telegraph through the board to the visible side. Before either of us makes a move the initial sighting is followed then by looking for any kind of damage elsewhere. It always surprises me just how much damage is caused by the points of the forks of a forklift that send a split through the edges of boards. Distortion will always mean loss of volume and even a small twist or cup can mean a loss in thickness of between 1/8″ and much more depending on how judicious you cut near lengths to.