It doesn’t matter who you are, it will happen to all of us. We can spend so much time invested into it and then it happens, the break-up. Maybe it has happened to you and you learned from it. Maybe you are going through it now, or maybe your ‘break up’ is yet to come, but it will happen. Sometimes it shows up out of nowhere and you didn’t see it coming. Other times we see signs of it failing and choose to ignore it. Secretly lying to ourselves and hoping it will go away. Either way, when the pieces shatter we can look and try to put the blame on a dozen reasons why it failed. But the truth of the matter is, it always comes down to us. We are the real reason for the failure because we didn’t pay attention and didn’t account for enough wood movement.

Yes, it’s true, our best-designed project can literally go to pieces if we don’t accurately accommodate for wood movement. I know in my case, of 25 years of woodworking, I can think of at least four cases where wood movement ruined my work. Each time it was because I ignored some basic rules. So let’s begin with some of the basics.

Wood movement results in the type or species of wood, the wood grain orientation, the moisture content of the wood, and the humidity of the environment where you are.

Wood Species– The list of different types of wood species is almost endless. The book The Real Wood Bible is a good reference for types, qualities, and uses of different woods, and it can help you choose something that might fit the specific requirements for your project. But for myself, I usually choose my wood type based on how I want the project to look. So for me, the next thing on my list is more important. Wood grain orientation.

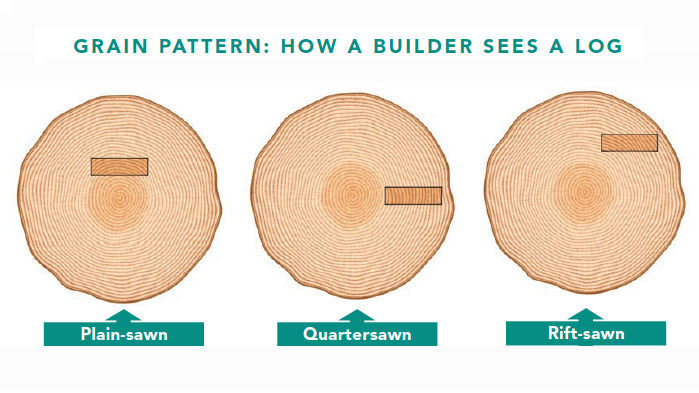

Wood Grain Orientation– When a log is cut into dimensional lumber it is usually cut one of three ways. Plain or Flat sawn, Rift sawn, or Quarter sawn. Each can have an advantage or disadvantage.

Plain Sawn- Plain-sawn wood yields the most lumber out of a log so for that reason it’s fairly cheap and in abundant supply. However, this type of cut results in the end grain growth rings having a series of arches or curves. These curves in time want to straighten out and this will result in warping.

Rift Sawn– Rift-sawn wood has the end grain that produces a series of growth rings that run at a diagonal angle of somewhere between 30-60 degrees. This is a much more desirable cut of wood making it much more stable, however, it comes at a higher price to purchase.

Quarter-sawn– Quarter-sawn wood has the end grain produce a series of growth rings 90 degrees to the face of the board. This in my opinion is the most stable, however, this is up for debate because others will say rift sawn is better. In either case, this wood is more expensive because it yields less out of the tree log when milling but it does greatly help prevent warpage. So let’s take a second and talk about warpage.

When you are selecting your material, even if it’s plain, riff, or quarter sawn, look carefully at the wood. You want to look for one of 4 ways that wood can warp. Twist, Bow, Cup, and Crook.

Each can pose its own unique problem. There are solutions to fix each of these warpages but if you don’t want to waste time or material it’s best to select good straight pieces of wood.

Moisture Content– Moisture content is the amount of water still within the cells of the wood. High levels of moisture content can cause warping, splitting, or cracking. The method by which wood is dried can affect the moisture content. If it is air dried it takes roughly a year for every inch thick of wood. Air-dried wood is cheaper to do but takes longer to dry. It’s easier on tools and as the wood dries it remains the same in color. However, the wood is subjected to more movement in seasonal changes.

Kiln-dried wood is a temperature-controlled environment that heats the wood to get rid of the water and controls the cooling down of the wood. This process can change the color of the wood and makes it a little bit more brittle, which can be harder on tools. The cost to kiln dry is more than air dried but it is faster and typically more stable. The best thing is to check your wood with a moisture meter. 6-8% is ideal moisture in the wood. But using the map below, you can see in my area of Ohio, it says 7-9%. And quite honestly, I’m comfortable using wood in the 12% range.

Humidity of the Environment- This is the last of the elements that can greatly affect wood movement. As the seasons change and the humidity in the air goes up the wood can absorb that extra moisture in the air and cause the wood to swell. Despite your best efforts of the wood selection and drying process, wood can still move, so it’s good to factor in some room on your project for the wood to move.

One method for factoring in the amount of movement is to follow this guideline.

First look at the EMC chart and find a city and state near where you might live. In my case, I’ll use Detroit MI. Take the highest EMC of the year. It’s showing 14.7 for the highest record. Subtract it from the lowest EMC of the year. Again in this case it’s 12.3. This gives me a difference of 2.4.

Then look at the next chart. This chart has different species of wood on it. It has a list for Quarter/Rift Sawn wood and a list for Plain sawn wood. The numbers are measures of the degree to which wood will change in size and dimension in relation to moisture content. (Dimensional Change Coefficient Value)

For another example, I’ll choose plain-sawn red oak. This gives me a coefficient value number of 0.0037.

The last thing I need to solve this puzzle is how wide my board is. Let’s say for this example it’s going to be 30” wide. Now I can put it all together.

30” wide board X 0.0037 coefficient value X EMC average 2.4 = 0.266

That’s just over ¼” of wood movement I can expect in the year. It will expand and contract that amount. Now, this is just a formula and should be considered as another tool used to help you factor in wood movement. It’s not an exact science.

So in summary, to help minimize wood movement involves the type of wood, the wood grain orientation, the amount of moisture in the wood, and the humidity where you live. These elements will help you control wood movement but you can never stop it. In a future article, I will discuss how to incorporate room to allow the wood to move without causing any damage.

Chad Stanton- Stanton Fine Furniture 2-27-2023