Applying paste wax to furniture is part of most furniture maker’s process. For closed pore woods, such as cherry or maple, clear paste wax is usually used. But when finishing furniture made from open pored woods (oak, mahogany, walnut), it is a common practice to apply a colored paste wax as a final step. Usually a black or very dark brown wax. For the Arts & Crafts / Craftsman / Mission pieces I have built using quarter sawn white oak, I’ve done it on every piece. It is a standard part of my finishing regimen. Recently, I finished up a commission to replace some worn painted plywood doors on a mid-century modern credenza with mahogany veneer doors, and I used dark brown wax there as well. Let’s look at the effect…

View fullsize

left waxed, right no wax

View fullsize

both with wax

View fullsize

left waxed, right no wax

View fullsize

both with wax

In these quarter sawn white oak door frames, the wax adds definition to the pores, and gives the wood more richness and depth. The overall color darkens slightly, but it is more about emphasizing the pores and corners.

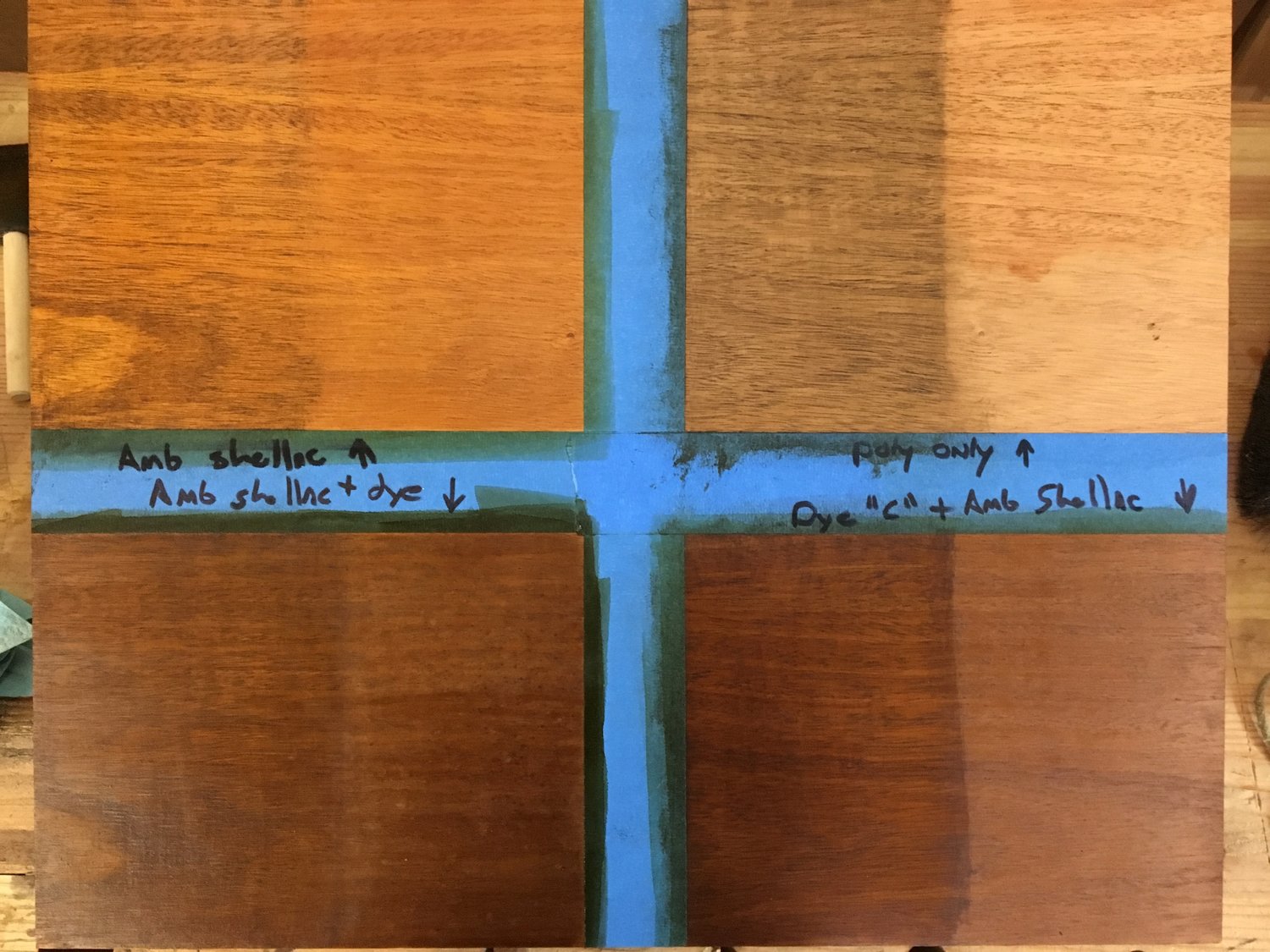

In the case of the credenza, I used the wax to match the existing finish on the outside of the case. In this piece, the mahogany veneer on the body had already been finished by a factory finishing process. I suspect it was a dark colored glaze (sort of a “wash coat” that only leaves colors in the pores & corners) topped with a tinted top coat. However, the doors I built were starting from bare mahogany. So instead of trying to do a glaze (something I don’t tend to do) and applying a tinted top coat, I approached it differently. After several rounds of testing, I found that first applying a coat of amber shellac, followed by several coats of clear wipe on polyurethane, THEN a final waxing with dark brown paste wax, resulted in a match for the original finish quite well.

the test board

clear coat, then dark wax

dye in clear coat, then waxed

dye in amber shellac, then waxed

amber shellac, then dark wax

Once I had the formula, I applied it to the finished piece…

View fullsize

original finish

View fullsize

new door detail

View fullsize

finished piece

With any final coat of wax, you can buff it to the desired sheen, from shiny to matte. I usually apply it using fine (0000) steel wool to knock of any dust nibs as I go, then buff with a cotton rag. The result is a smooth, deep finish with the sheen tailored to your taste. So if you’re new to finishing, or just new to wax, try it out (ON TEST BOARDS) and see what it can do for your finishes.