These burls greet you when pulling up to the sales building at Goosebay Sawmill and Lumber.

I’m behind on getting this post out. Life has gotten pretty busy lately. I started a new job in December that gets me home at nearly 8:00 every night. But I’m enjoying it so much I’m scurrying out the door every morning at 6:30 to catch the early train so I can get back to work.

That doesn’t leave a lot of time for woodworking or other things during the week. At least I can get up to an hour of writing or editing or coding done on the train. Unless that clubbed-over-the-head feeling catches up with me and I have to zone out until my stop.

Meanwhile, I’m progressing on my new video course and my book on the weekends. Ah, if only I had more time…I would just fill it with more stuff!

A teaser still from the new video: comparing the results of 2 of the methods for roughing out cabriole legs in cherry.

This Lie-Nielsen Hand Tool Event was held February 26-27 at Goosebay Sawmill and Lumber in Chichester, NH. This was their second year doing this, and my first time there.

I was unfamiliar with them before this event, and I must say I’ve been missing out! They’re a family-owned business that’s been there since the late ’70’s. They specialize in the more figured hardwoods.

A variety of figured stock in curly, tiger, bird’s eye maple.

That’s an understatement. There was so much curly maple, tiger maple, bird’s eye maple, spalted maple, plus other figured wood and more burls than I’ve ever seen. Also lots of nice quartersawn woods (I saw some beautiful QS ash that must have been 16′ long), as well as plenty of exotics. The salesroom has racks of turning blanks. It really was spectacular.

Some of the main lumber racks.

Turning blanks in the sales room.

I picked up a few pieces just to play with. I don’t have any experience with these really figured woods, but I’ve admired everything I’ve ever seen made with them. Time to get some experience with them. I’ll make some nice little boxes, always a good learner project.

As hardwood dealers go, it’s not a large warehouse. But it’s packed with fine quality stuff. They have an extensive log yard that they lease to a logging company. These days they limit most of their custom sawing to the most spectacular logs. There were trucks arriving even on Saturday. One driver said he had a gorgeous cherry that was 30″ across at the small end.

And trucks! With big grappling arms!

They weren’t sawing during the event, but I was amazed by a debarked log sitting on the mill. You could see the chatoyance of the curl even in the whole log.

On the saw feeder rack, you can see the curl shine in that top log.

They also have a kiln on site, so they’re able to process whole logs from the yard into final lumber for the warehouse.

The operation was started over 35 years ago by Carl Sr. and Carl Jr. Now it’s on the third generation Carl. So it’s Carl Jr. and and his son Carl (it takes everyone a few minutes to sort out that Carl Jr. is the elder!).

Their prices are very reasonable, especially considering how gorgeous this wood is. If you’re not in the area, they ship, no order too small. Here’s their price list and shipping information.

They were also great people to work with, so I’m really looking forward to next year’s event. But I’ll be back before then with an empty van and credit card in hand. Look forward to seeing those projects here.

This appeared to one of the best-attended Hand Tool Events I’ve seen. The room was already full when I walked in Friday morning, and it stayed that way until late afternoon. Saturday was even busier, with a good crowd right up to the end. People were admiring the wood as much the tools, so hopefully it was fruitful for both Lie-Nielsen and Goosebay.

This event was run by Kirsten Lie-Nielsen, Danielle Byrd, and Tim Lovett.

Kirsten running the register and taking orders.

Danielle demonstrating handplane use.

Deneb Puchalski’s beautiful small toolbox.

The demonstrators at this event were Tom McLaughlin, Peter Follansbee, Travis Knapp, Matt Bicksford, Gary R. Wood, and Mike DiMaggio.

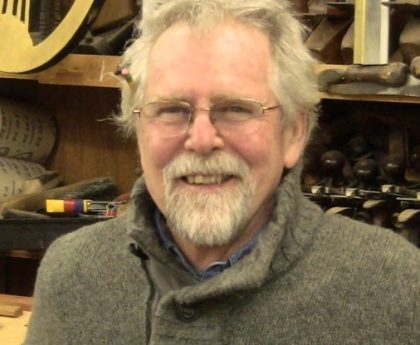

Tom McLaughlin of EPIC Woodworking. You may have seen him on several episodes of “Rough Cut” with Tommy Mac.

Peter Follansbee carving spoons.

Gary R. Wood demonstrating French polishing.

Matt Bickford’s table of beautiful wooden moulding planes, and his spectacular book, “Mouldings In Practice”. He also now has a DVD!

Mike DiMaggio is the new president of the Guild Of New Hampshire Woodworkers. He had a small bench setup next to mine with a Tormek and was sharpening an endless supply of chisels as he talked to people.

One thing that caught my attention was what he was doing with the backs. I noticed him polishing them on a stone, so I asked about it. He said it was a Spyderco fine ceramic stone that put a mirror finish on them.

He said some people have difficulty with them because they don’t go through the coarser stages properly, and don’t clean the surface properly, so it gets glazed and ineffective. He says a little scrubbing with Bar Keepers Friend is all it takes.

He offered to let me use it, so I tried my antique paring chisel on it. I keep a near-mirror polish on its back by working up through 1500-grit wet/dry automotive sandpaper on a polished marble floor tile. I was amazed by the Spyderco. In 30 seconds it put a truly mirror polish on the tool.

Mike said these are often available on eBay from people who haven’t used them much. He also has an ultra-fine that he likes. I ended up ordering a fine and ultra-fine from an eBay seller at a reasonable price; they’re winging their way toward me as I type.

I’ll try these on a variety of tools and see if they produce a noticeable difference in performance or change in my sharpening procedures.

As with the last few events I’ve done, I was promoting my Intro To Hand Tools online video course, as well as talking to people about learning to make violins. I’ve made very little progress on the luthiery work, primarily due to the aforementioned demands on my time, but it always makes a good topic for engaging people who are less interested in hand tool basics.

My setup, two benches and video running in the background.

I had my 3/4″ in-cannel paring gouge (gorgeously tuned up thanks to Yoav Liebrman’s writeup; he showed how to do the inside of an out-cannel gouge, I took it the next step to do both sides of in- and out-cannel tools), so another good way to engage people was to stand at the bench peeling big rounded shavings from a piece of pine with it. I’d have people run their fingers over the surface left behind; it was like glass.

Then I’d offer the gouge to them to try out. Most found it pretty enticing. Typically they’d go in too deep with it, but were quickly able to get it under control. It’s just very satisfying.

As usual by the end of the day my bench is overloaded with stuff!

Travis was selling these leather holdfast boots. I thought they were a brilliant idea, so I got a pack of 5.

A number of people took cards for the course. The next offering starts May 11. Note that once you register for the course, you have unlimited access to watch the videos online. During the actual active period of the course, you have email and online discussion access; once that course reaches its end date, these are closed. But you can watch the videos over and over as much as you want, since it’s a lot of information and may take some time to work through in the shop.

SOURCE: Close Grain – Read entire story here.